How to Make Coco Sugar, Coco Nectar, Sap Drink and Organic Vinegar.

Sequential toddy & nut production (SCTNP) technology which produces toddy and nuts from the same spathe of the palms has provided the farmers to increase farm income without sacrificing the copra products and fully maximize the economic potential of the palms with the addition of another product which is the coconut sap or toddy. It has high total sugar, ascorbic acid, phosphorus, and rich in amino acids, vitamins and minerals.

It can be an alternative source of sugar and other products like sap drink (fresh cooled beverage), coco nectar (syrup) and sap vinegar which are high value food products.

It can be an alternative source of sugar and other products like sap drink (fresh cooled beverage), coco nectar (syrup) and sap vinegar which are high value food products.

Tapping & harvesting of toddy

Tapping is done twice a day. Harvesting of toddy can be done in morning (taken before 8am) for the production of ‘tuba’ or vinegar while for the production of fresh sap drink, nectar and sugar, it is best to used the afternoon harvest (taken not later than 3pm) which is sweeter than the morning harvest. To produce sweet toddy, it is necessary that all tools and containers to be used should be clean at all times. Adding of lime to the receptacle prevents the sap from fermentation.

Toddy processing

The conversion of toddy into sap drink, coco nectar and sugar involves a simple operation. As the coconut sap is highly perishable due to the yeast microflora, the harvested sap should be immediately processed by boiling for 1/2 hour in a large cast iron pan. This process prevents the sap from fermentation.

Sap Drink

This can be simply done immediately by pasteurizing (heating at 60oC) the toddy. The toddy is then poured separately in the desired container tightly sealed and placed in the refrigerator. If hygienically prepared, the sap drink can be stored until 3 days without deterioration.

Coco Nectar/Syrup

Further boiling of toddy until it reaches 110oC temperature or sticky under a moderate to very low heat. The sticky liquid shall be allowed to cool then poured into a desired container.

Coco Sugar

Boil coco sap to evaporate the water under moderate heat with occasional stirring until liquid thickens at 115oC. Remove it from the flame when it begins to become very sticky. Continue mixing until it becomes granular. Air dry the brown sugar before placing them in a packaging material.

Sap Natural/Organic Vinegar

Pour toddy in a wide large container with a clean netted cover to allow aeration and prevent entrance of dirt and foreign objects. After 5-10 days fermentation period in a well ventilated room., the sap can be harvested as vinegar. To maintain the desired quality of the matured vinegar (with at least 4% acidity), pasteurize it by boiling for 5-10 minutes at 60-65oC, allow the vinegar to cool before placing in very clean bottles and then cover tightly and sealed.

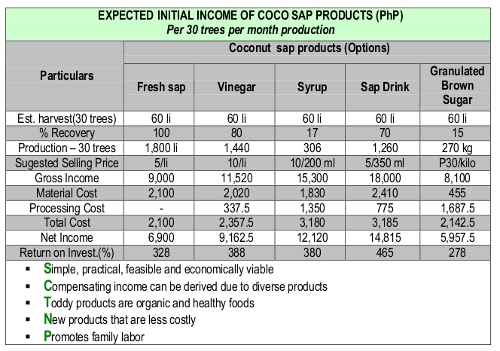

Increase your Farm Income thru Product Diversification Scheme.

For more information, Write or call:

1) CANFARMS Project

Zamboanga Research Center, Philippine Coconut Authority,

San Ramon, Zamboanga City

Tele Fax No. (062) 991- 5087,

Email: wesmarrdec@wmsu.edu.ph

2) Agronomy & Soils Division

Davao Research Center, Philippine Coconut Authority,

Bago Oshiro, Davao City

Tel. No. (082) 293-0161,

Email: pca-drc@interasia.com.ph; milsecretaria@yahoo.com

3) Agricultural Research Management Department Research, Development and Extension Branch,

Philippine Coconut Authority, Diliman, Quezon City

Tel. No. (02) 426-1398 / 920-0415,

Email: sevmagat@mozcom.com

Sources: Techno Guide Sheet No. 8, Dept. of Agriculture, Philippine Coconut Authority

Do you like this Money Making Business and Ideas? then please consider subscribing to our RSS feed and have new articles sent directly to your inbox.

which is which? cocowater or coco nectar? i think i’m gonna go with cocowater.

@Grace, you can try this recipe in this link: http://www.pinoybisnes.com/food-business/how-to-make-coco-candy/

How to make coco candy?

As a side note, the Coco Nectar mentioned above is now for sale online via http://mutyaman.com. We are the first authorized online distributor for Dr. Gerry’s Coco Nectar, and we ship to all of the Philippines. Also, if anyone reading this is interested in becoming a distributor, please feel free to use the Contact link on the site, we are always seeking wider distribution of this product.