(Pilsen, Czech Republic – 8/8/2022) – Doosan Škoda Power delivered a 270 MW steam turbine with accessories for the Metsä Group’s fossil-free bioproduct mill in Kemi, Finland. The mill is designed to produce about 1.5 million tonnes of softwood and hardwood pulp per year. The value of the investment is EUR 1.85 billion and it is the largest investment ever made by the Finnish forestry industry. The mill will be started-up as planned at the third quarter of 2023.

The bioproduct mill will operate without using any fossil fuels and the surplus electricity produced will be supplied to the national grid. The new mill will replace current Metsä Group pulp mill in Kemi and will be the largest wood processing plant in the northern hemisphere. The mill is being built with the Best Available Technology (BAT) or even more advanced technology. The Kemi bioproduct mill produces 1.5 million tonnes of softwood and hardwood pulp per year, as well as other bioproducts. The new mill will produce 2.0 TWh of renewable electricity every year, equivalent to about 2.5 per cent of Finland’s total electricity production. The mill will have an electricity self-sufficiency rate of 250%, and this will further strengthen Metsä Group’s position as a major electricity producer relying on renewable Finnish fuels.

“We have set high material, energy and environmental targets for the Kemi bioproduct mill. Only the best available technology will be used. That is why we require that also our partners provide the technically most reliable solutions. Based on our experience, Doosan Skoda Power solutions fits into this category,” said Jari-Pekka Johansson, Director of the bioproduct mill project at Metsä Fibre.

„The engineering, procurement and manufacturing phase of the project has been a challenge due to the COVID-19 restrictions, which caused significant delays together with increase in the raw material costs. Despite all these challenges and thanks to the extraordinary effort, our team managed to deliver in full as per the client requirements. Heavy lifts have currently been carried out on the construction site, mechanical assembly continues, and commissioning will follow. We are staying focused to keeping up the good work,“ said Jindřich Závodný, Project Manager at Doosan Škoda Power.

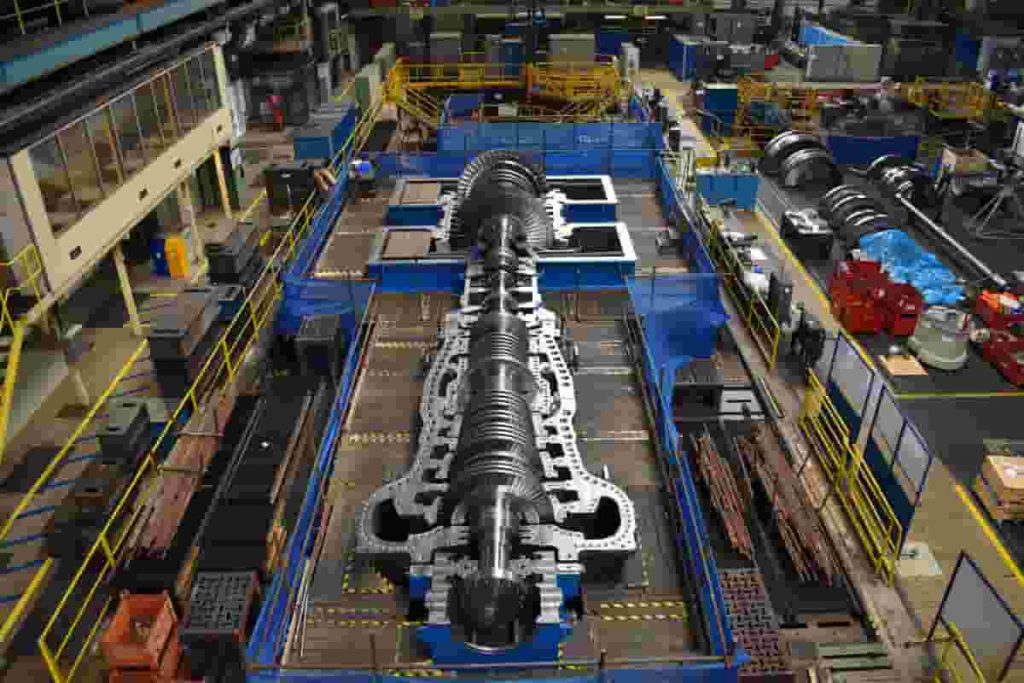

As part of the contract, Doosan Skoda Power will also deliver a generator, condenser, and rest of the accessories of steam turbine. The turbine itself has a tailor-made condensing turbine section solution and is equipped with two steam bleed connections of different pressure levels. Condenser is hanging on low-pressure part without any support from below. Both high- and low-pressure parts of steam turbine can be operated independently.

ABOUT DOOSAN ŠKODA POWER

Doosan Škoda Power is part of a strong group of companies united under the Doosan Group, which supplies leading technologies and services of the highest quality and value to customers all over the world.

Doosan Škoda Power is a leading global manufacturer and supplier of power plant equipment, especially steam turbine/generator sets with outputs between 3 and 1,200 MW. The company has extensive experience and references in applications for steam-driven and fossil-fuel-fired power plants, CHPs, nuclear and solar power plants (CSPs), biomass plants, energy-from-waste plants and in industrial applications for oil and gas, pulp and paper, and many more. As regards services, the company offers retrofits and modernization (R&M) of installed OEM and non-OEM equipment, overhauls and long-term service including spare parts delivery. Annual research and development investments guarantee high quality products that meet specific customer requirements.