Introduction

A successful supply chain is the foundation of any successful manufacturing organisation. As the skeletal system of the production process, the supply chain generates a large amount of data. Although vital, this data is tough to collect, evaluate, and extract insights from in order to optimise your supply chain. Here comes supply chain analytics.

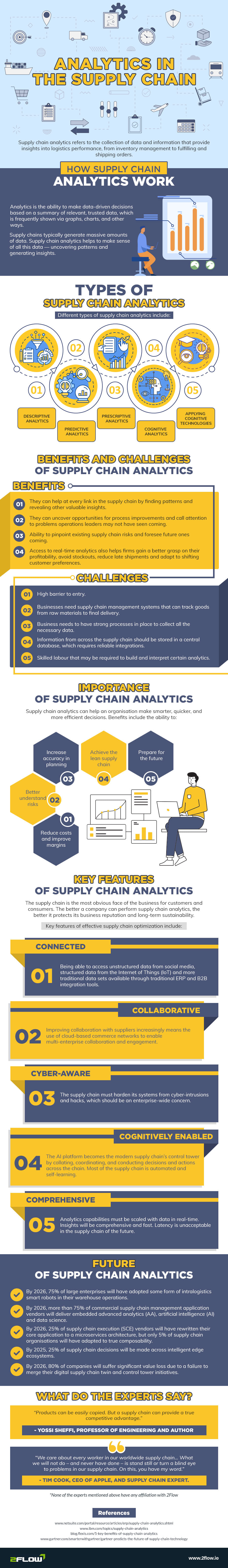

Analytics allows you to make informed business decisions based on a summary of usable, trustworthy data, which is frequently visualised using charts, graphs, reports, and other tools. Supply chain analytics make sense of a sea of data by breaking it down into useable parts, recognising patterns, and delivering intelligent solutions. These data-driven insights will be critical in the coming decade, as analytics usage will soar. These well-informed judgments result in better operations planning, a more efficient supply chain, and, ultimately, increased profitability.

What Is the Importance of Supply Chain Analytics?

Wouldn’t you use a tool that foresaw the future if you had access to it? You would, of course. Are we claiming that supply chain analytics can foresee the future perfectly? No. Are we suggesting that supply chain analytics identifies patterns and accurately anticipates future trends? Yes. Supply chain analytics tools enable firms to focus on current patterns, collect data from operations in real-time and use big data to understand market trends, measure demand, and decide accurate pricing plans.

Here are some of the most important reasons why supply chain analytics are critical to manufacturing success:

- Improve supply chain planning

- Increase flexibility within the supply chain

- Recognise trends or dangers in the supply chain.

- Gain efficiency in staffing or sourcing

- Understand key aspects of business

Check out the infographic below by 2Flow which takes a further look into Supply Chain Analytics and the importance of having them in place.