Increasing the amount of stainless steel used in automobiles could increase the number of industries that want to buy 304 stainless steel tube. It has many attributes that make it a good choice for fabrication of different parts of a car.

In a variety of sectors, people buy 304 stainless steel tube because of its corrosion-resistant property as well as its ability to withstand high pressure. Such properties and more make it ideal for the automobile industry. Let us take a look at some of its application currently and in the future.

Car Exhaust Pipes

This is the most common part of the automobile that utilizes stainless steel. It is particularly useful around the area that connects to the catalytic converter. It is necessary to reduce the emission of harmful combustion gases. It transforms carbon monoxide, nitrogen oxide, and hydrocarbons into less harmful elements. This process however can be a problem for the metals used for the exhaust since it induces oxidation which results in corrosion. Stainless steel however can resist corrosion as well as the change in temperature which makes it the best choice for this purpose.

Different grades of stainless steel alloys are used in the exhaust. 304 is particularly preferred for areas that have to withstand cold temperature while the 309 and 308 are placed in areas that need to withstand high temperature.

Motor Structural Application

Features of stainless steel make it applicable to the structural design of motor vehicles. First of all, it is crashworthy material. This means that it can protect passengers in case of a crash. This is interesting considering that at the same time, it is a light metal. Although it is lightweight, stainless steel can absorb impact and prevent it from being transferred to the passenger.

The ability to resist corrosion is also worth considering when designing the structure of a vehicle. It will make the frame of the vehicle durable. Whether it is exposed to moisture, oxygen, or even harsh weather, it will remain strong.

Fuel Tank

The advantages of having a fuel tank made from stainless steel will leave you wondering why this is not the material most car makers use to make fuel tanks. For starters, stainless steel would cut down the weight of a car by about 3kgs and yet the material used is crashworthy.

For those who care about the environment, they would like the fact that in comparison to plastic, stainless steel is 100 percent recyclable, so no harm is done to the environment when the tank is no longer needed.

In terms of maintenance, there is no need to maintain a stainless-steel tank, it will serve you for the entire duration of the automobile’s life.

Catalytic Converter

Since the use of stainless steel in the exhaust system has proved successful, it is only natural that we look into its use in the catalytic converter which is connected to the exhaust system. We could consider replacing the all-ceramic catalytic converter with a lighter option like stainless steel. Steel foil of about 40 microns can significantly slash the weight of the converter system. But that is not all, steel is a good conductor that will make preheating with electricity easier and improving the catalytic effect as soon as the engine is started, thus helping it reach working temperature in a few seconds.

Car Finishing

Because of its high corrosion resistance, stainless steel provides a great finishing for different parts of the car. In the interior, the seatbelt buckles are molded from stainless steel. On the outside, parts of the wipers are made from the same material to ensure they remain rust-free. In the engine, the head gaskets and pump body are also made from stainless steel.

There can be many other applications within the engine and on the body of the car that can be made from stainless steel either because it is aesthetically pleasing or in order to provide strong material that will resist corrosion. Some automakers have also used it in suspensions and they have proved to have a long life.

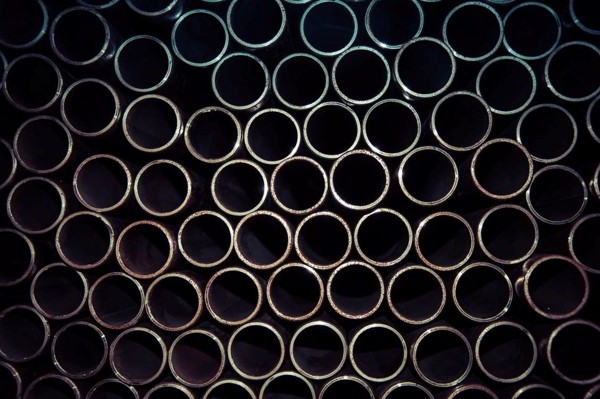

Space Frame Chassis

For the design of sports cars, it would be an advantage to have the space frame chassis designed from tubular stainless steel material. This reduces the weight of the vehicle while providing a solid structure to keep the vehicle’s shape. Stainless steel is also easier to shape and fabricate so making the vehicle will be easier.

Stainless steel has proved to be effective for use in other industries including food processing, architecture as well as the medical field. There are varieties of alloys to choose from with properties that would work well in different applications. With further experiments, the automobile industry can learn more relevant applications that can make vehicles safer, faster, and lighter. Despite its cost, it is a durable option with a range of opportunities to explorethat make it a worthwhile investment.