When it comes to the maintenance of the aircraft, a certain level of aircraft tools control mechanism is needed to ensure that no tools are left on the aircraft or around the aircraft. Tool control system comes in many forms and different types of aircraft require different aircraft tools. Before an aircraft takes off in the air, a tool control expert should ensure that every tool is in the right place in the storage area.

There are few important things you should know about tool control and how it can be helpful for business. Tool control is an important part of foreign object damage (FOD) control in aviation. Damage from foreign objects is a major concern for aircraft safety. By any chance if the tools are left behind, it can jam the flight control, can cause damage to the engine and can also lead to fatalities.

There are few things that one should follow to avoid FOD damage from aircraft tools:

- Your tools should be marked: aircraft tools are marked with serial numbers for easy identification as it helps the tool control management to keep a check on all the tools. Any tool left in the aircraft can compromise flight safety hence it helps identify the user of the tool and can be returned. Large organizations use RFID and barcode technology in verifying aircraft tools. The company can improve its tool control system by making sure that the engineers only carry the required tools for particular work instead of taking the whole tool kit. There are a vast array of aircraft tools and marking all of them is quite impossible. You must ensure that irrelevant tools are removed from the site completely.

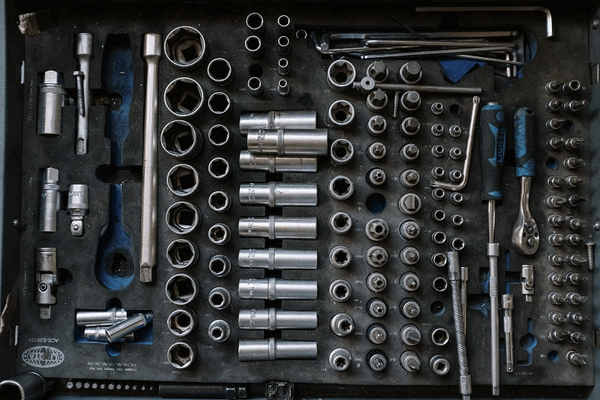

- Use of Shadow boards: Shadow boards have been used by the aviation industry for many years because its use as a part of aircraft tools management, allows the controller to see and count the tools and know which tools are missing. You can trace around the different tools in their storage space with a permanent marker which will let you see all the tools in one glance.

- Cut-outs made of foams: Foam cutouts are another way to easily identify missing tools. The advantage of foam cut-out is that it is used on a horizontal surface like toolboxes or drawers. Though the Shadow boxes are vertical, making foam boards that sit at a slight angle from vertical prevent aircraft tools from falling out. Foam cut-outs not only provide the visual cue for tool control but also give the added advantage of keeping tools neatly and securely stored in a place.

- Photograph of tool board: To provide assistance with the aircraft tool control system one should take a photograph of the shadow board or foam tray for a quick reference. It can give you an idea of which tools belongs to which empty places. This adds another layer to the tool control system and it allows any person who is not familiar with the tools to find out which tools are missing because of the size and shape of the item cut out from the board. You may not be able to identify regular shapes without a photograph but photographs are very much useful in tool control.

Conclusion:

Save aircraft from getting damaged due to FOD and strictly follow aircraft tool control methods to avert any accident. Ensure you follow all the guidelines mentioned by the safety regulation department of the aviation industry. Choosing the right aircraft tools helps to maintain your airplane. Failure to follow the correct protocol can lead to hefty fines, termination of the contract, and even penalties.