Austria, Vienna, Nov. 26, 2024 (GLOBE NEWSWIRE) — Single-component acrylic adhesives are a type of adhesive that consists of acrylic polymer as its main ingredient. Epoxy is versatile in bonding various materials like plastic, metal, glass, and wood, making it ideal for adhesives. These are known for their flexibility, stability, and exceptional endurance in various weather conditions and over time. Acrylic adhesives come in solvent-based or water-based forms, depending on the chosen marketing approach. The automotive, construction, electronics, and packaging sectors have widely embraced these products due to their highly effective application on various materials.

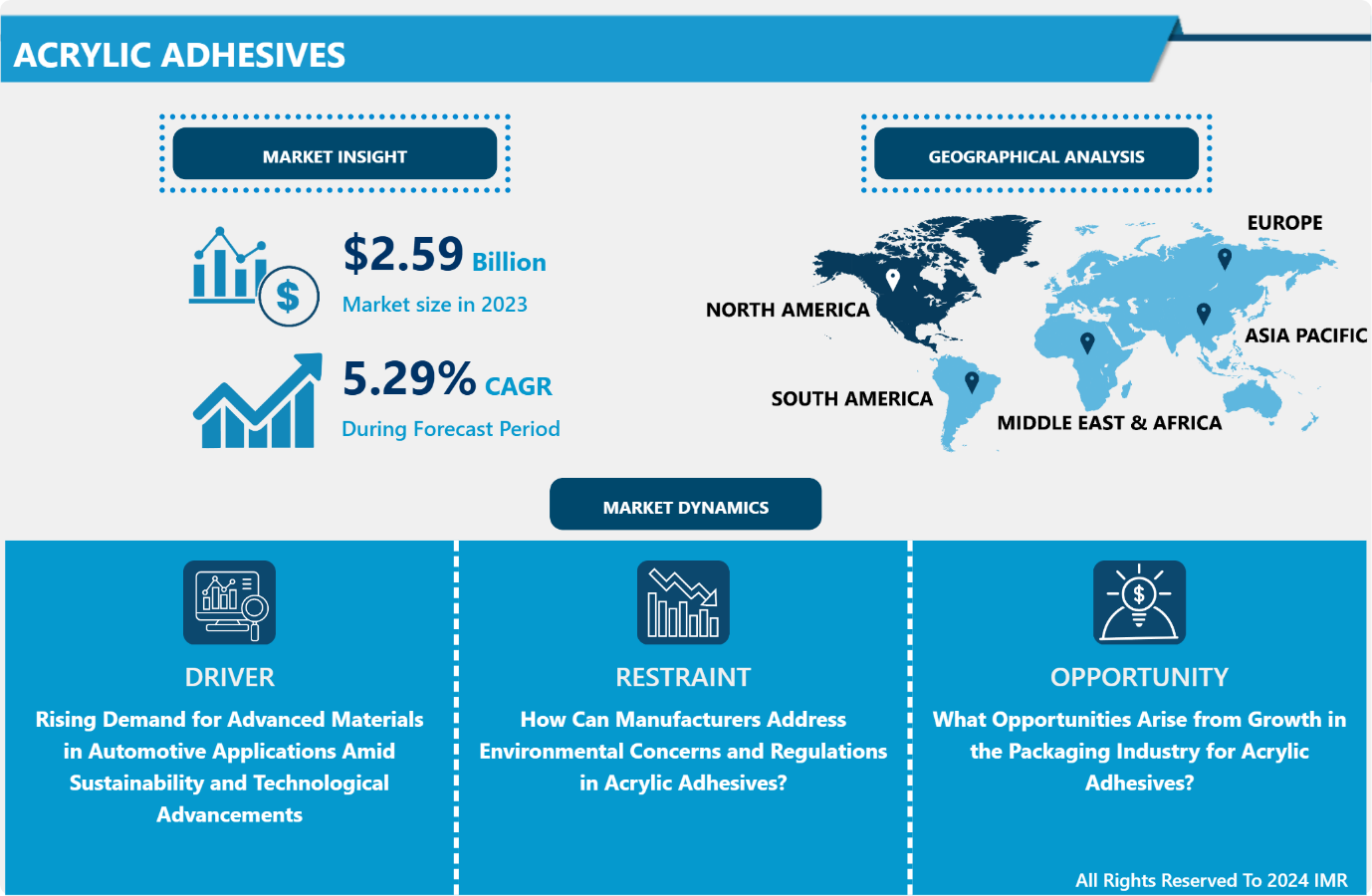

Introspective Market Research has unveiled its latest market study, titled “Acrylic Adhesives Market,” providing a comprehensive outlook on the future of this premium delicacy. According to the report, the global acrylic adhesives market was valued at USD 2.59 billion in 2023 and is poised for significant expansion, with projections indicating a climb to USD 4.12 billion by 2032. This anticipated growth represents an impressive CAGR of 5.29% from 2024 to 2032.

Over the past decade, the worldwide need for acrylic adhesives has been steadily on the rise, primarily due to its versatile applications in sectors such as automotive, construction, packaging, electronics, and various specialized industries. Acrylic adhesives are chosen for their strong bonding, ability to withstand harsh conditions, and quick curing. Known for their excellent performance in both structural and non-structural applications, they are based on a poly acrylic material. The increasing utilization of sleek and lightweight cars has resulted in the adoption of acrylic adhesives in the automotive sector to replace traditional mechanical fasteners, ultimately decreasing vehicle weight and fuel consumption.

In the construction industry, acrylic adhesive is used to bond various substrates like glass, metal, and plastics to improve construction practices. The electronics industry also utilizes these adhesives for their ability to provide rigid connections in compact and fragile devices. Asia-Pacific is the market leader in terms of regions due to the rise of industrial and urban development in countries such as China, India and Japan. North America and Europe rank second because of the utilization of new technology and commitment to sustainable construction practices. However, there are certain elements that influence the growth of the market, including the fluctuation of raw material prices and the rising regulatory demands. Yet, there are active research and development trends aiming to enhance the essential characteristics of acrylic adhesives in preparation for upcoming market growth opportunities.

Download Sample 250 Pages of Acrylic Adhesives Market Report@ https://introspectivemarketresearch.com/request/17084

Notable Drivers of the Acrylic Adhesives Market

Rising Demand for Advanced Materials in Automotive Applications Amid Sustainability and Technological Advancements:

The increased popularity of acrylic adhesives in automotive use is a result of their outstanding characteristics and compatibility with changing industry patterns. Acrylic adhesives are excellent for use in automotive assembly, providing strong resistance to moisture and changes in temperature. Their capacity to create strong connections makes them more favorable than conventional mechanical fasteners such as bolts and rivets, especially in the production of lightweight cars, an essential approach to decreasing emissions and enhancing fuel economy.

With the automotive industry moving towards lighter materials, acrylic adhesives are more and more being utilized in areas like body-in-white, interior trim, and structural joining. These adhesives allow for smooth bonding of various structures, improving the aesthetics and performance of vehicles. Their ability to adapt in structural adhesive design also promotes creative manufacturing strategies.

Safety and adhering to regulations are also important factors that drive demand. Acrylic adhesives help meet strict safety standards by improving the structural integrity and overall performance of vehicles, contributing to their crashworthiness. Moreover, the surge in electric vehicles (EVs) has increased the demand for acrylic adhesives for putting together important EV parts like batteries and electronic components. The significance of acrylic adhesives in contemporary automotive manufacturing has been emphasized by a combination of light weighting initiatives, regulatory pressures, and the rise of EVs. Their distinct characteristics and adaptability are crucial for enhancing vehicle efficiency, safety, and functionality, guaranteeing their ongoing relevance in the automotive sector.

Surging Demand for Sustainable Construction Materials Amid Green Building Trends and Innovation

The increasing demand for acrylic adhesives in construction is driven by their critical role in enhancing building envelope performance in commercial and residential architecture. The building envelope, which separates a structure’s interior from the external environment, plays a vital role in sustainability by controlling moisture, noise, temperature, and air pressure. A properly sealed envelope is essential for reducing energy loss, particularly since air leakage can account for up to 20% of a building’s HVAC energy consumption. Materials like membranes, spray foams, and sealants are indispensable for effective sealing, ensuring improved occupant comfort, lower energy use, and reduced operating costs.

Adhesives and sealants are fundamental to construction, offering solutions for bonding, joining, and sealing. These materials are available in diverse forms liquids, pastes, tapes, and films and include types such as epoxy, cyanoacrylate, and polyurethane adhesives. Acrylic adhesives are particularly valued for their durability, weather resistance, and versatility, making them ideal for structural bonding and insulation applications. Similarly, sealants like silicone, polyurethane, and acrylic provide robust barriers against water and air while maintaining flexibility and resilience under dynamic conditions. Acrylic sealants are especially effective in weatherproofing and gap-filling, contributing to the longevity and efficiency of buildings.

With the growing emphasis on sustainable and energy-efficient construction, the adoption of high-performance adhesives and sealants is rising. These materials not only enhance structural integrity but also support the global push toward reducing carbon footprints and achieving energy efficiency in modern architecture.

How Can Manufacturers Address Environmental Concerns and Regulations in Acrylic Adhesives?

Despite its versatility and eco-friendliness, the acrylic adhesives market is dealing with various environmental issues as it continues to expand. A primary concern is the release of volatile organic compounds (VOCs) from numerous conventional adhesives. Volatile organic compounds (VOCs) play a major role in air pollution and climate change, prompting worries about their effects on the environment and public health. As the sector grows, more stringent rules on VOC emissions are being put in place to reduce their impact.

A further issue is the exhaustion of finite resources needed to make acrylic adhesives. Obtaining and utilizing these resources leads to resource depletion, posing a significant sustainability challenge for the industry. Furthermore, incorrect disposal of adhesive waste presents a notable environmental hazard. Improper disposal of adhesives can lead to pollution, impacting soil, water, and wildlife. There is an increasing focus on environmental issues, leading governments globally to implement more stringent regulations to reduce the environmental effects of adhesives. Addressing these concerns is becoming more crucial as the industry expands and environmental regulations become stricter.

“Research made simple and affordable – Trusted Research Tailored just for you – IMR Knowledge Cluster”

https://www.imrknowledgecluster.com/

What Opportunities Arise from Growth in the Packaging Industry for Acrylic Adhesives?

The packaging sector is seeing continuous expansion fueled by changing consumer preferences, such as the increase in single-person households and a rising need for convenience. This has resulted in a greater emphasis on packaging solutions that are sustainable, user-friendly, and adaptable. In line with this trend, acrylic water-based lamination adhesives are now vital in the packaging industry. These adhesives are highly appreciated for their excellent bonding strength, clear appearance, and ability to withstand various environmental conditions, making them perfect for both food and non-food packaging purposes. Acrylic adhesives are highly efficient for adhering materials like aluminum foil, PET, PVC, and paper, and are frequently utilized in pouches, liners, and tear-resistant paper items. Their capacity to uphold a pristine, transparent appearance makes them perfect for premium, visually pleasing packaging. Acrylic adhesives are more frequently utilized in producing flexible packaging with features such as secure seals, portion control, and easy handling due to the growing demand for this type of packaging.

The worldwide packaging industry is changing to adapt to the demands of a new consumer environment, with flexible packaging projected to be a significant area of expansion. The shift is also impacted by an emphasis on sustainability, as more businesses are incorporating environmentally friendly materials and practices. Consequently, there is a growing need for high-performance adhesives that can accommodate these advancements, making acrylic adhesives a key element in the changing packaging sector.

Key Manufacturers

Market key players and organizations within a specific industry or market that significantly influence its dynamics. Identifying these key players is essential for understanding competitive positioning, market trends, and strategic opportunities.

- Henkel AG & Co. KGaA (Germany)

- 3M Company (USA)

- Arkema Group (France)

- H.B. Fuller Company (USA)

- Sika AG (Switzerland)

- Avery Dennison Corporation (USA)

- Illinois Tool Works Inc. (USA)

- Bostik SA (an Arkema company) (France)

- Huntsman Corporation (USA)

- Permabond LLC (USA)

- ReVital Polymers (Canada),

- Dow (USA)

- Hubei Huitian New Materials Co. Ltd (China)

- Jowat SE (Germany)

- Kangda New Materials (Group) Co., Ltd. (China)

- MAPEI S.p.A. (Italy)

- NANPAO RESINS CHEMICAL GROUP (Taiwan)

- Pidilite Industries Ltd. (India)

- Sika AG (Switzerland)

- Soudal Holding N.V. (Belgium), and Others Active Players.

In September 2024, AICA Asia Pacific Holding Pte. Ltd. (AAPH) acquired a 51% stake in ADB Sealant Co., Ltd. (ADBS), a subsidiary of Applied DB Public Company Limited (ADB). This strategic acquisition increases ADBS’s registered capital to 645.09 million baht, strengthening its position as a leader in industrial adhesives and sealants. ADBS serves key industries including real estate, construction, and electronics, solidifying its influence in these sectors.

In May 2024, Dow agreed to sell its flexible packaging laminating adhesives business to Arkema for $150 million, part of Dow’s strategy to focus on high-value downstream businesses. This sale supports Dow’s Decarbonize & Grow and Transform the Waste strategies, aiming for $3bn in annual earnings growth by 2030. The transaction includes five manufacturing sites in Italy, the US, and Mexico, enhancing Arkema’s position in the flexible packaging market, especially in food and medical sectors.

In May 2024, H.B. Fuller, the largest pureplay adhesives company globally, acquired ND Industries Inc., a leader in specialty adhesives and fastener locking/sealing solutions for automotive, electronics, aerospace, and other sectors. This acquisition supports H.B. Fuller’s growth strategy, enhancing its portfolio in the functional coatings, adhesives, sealants, and elastomers (CASE) market. ND Industries’ Vibra-Tite® brand will be integrated into H.B. Fuller’s existing product range, including epoxy, cyanoacrylate, UV curable, and anaerobic products.

In August 2023, Bostik, part of Arkema, launched the first all-temperature, wash-off label adhesive, Flexcryl ClearCycle 1000. This innovative adhesive is recognized by the Association of Plastic Recyclers (APR) for meeting or exceeding its Critical Guidance Criteria. It enhances PET bottle label recycling, contributing significantly to sustainable recycling streams, and supports Bostik’s commitment to sustainable solutions.

Do you need any industry insights on Acrylic Adhesives Market, Make an enquiry now >> https://introspectivemarketresearch.com/inquiry/17084

Key Segments of Market Report

By Type:

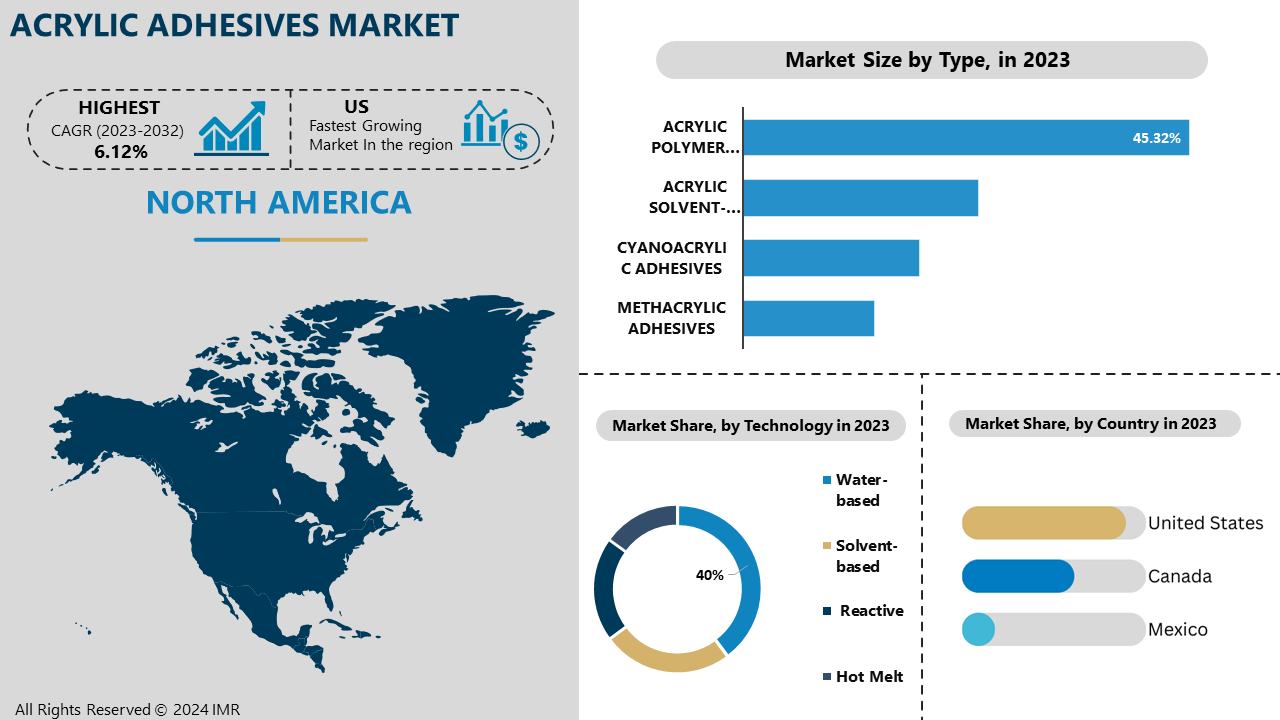

Acrylic Solvent-Based Adhesives are projected to lead the market for Acrylic Adhesives in the forecasted period. These adhesives have strong bonding abilities and are highly resistant to heat and moisture, which makes them perfect for use in industries such as automotive manufacturing and construction. Acrylic Polymer Emulsions, which are water-based and renowned for their eco-friendly characteristics, are extensively utilized in paper and packaging industries. Cyanoacrylic adhesives, also called super glue, offer fast bonding on various materials such as metal, plastic, and ceramics, providing strong adhesion and quick drying. Methacrylic adhesives, known for their enhanced flexibility and durability, are becoming more popular in the assembly of medical devices and manufacturing of electronics, particularly in applications where biocompatibility and resistance to harsh environments are essential. Advancements in adhesive technologies are improving performance, while the increasing need in industries like automotive, electronics, and healthcare for dependable and effective bonding solutions is fueling market growth.

By Technology:

The market for Acrylic Adhesives is divided based on technology, including waterborne, solvent borne, reactive, and hot melt adhesives. Water-based acrylic adhesives are becoming more popular because of their minimal VOC emissions, eco-friendly properties, and simple application, making them perfect for construction, automotive, and packaging sectors. Solvent-based acrylic adhesives provide strong adhesive qualities and quick curing times, making them ideal for uses where emissions from solvents are not a significant worry. Reactive acrylic adhesives are extremely flexible and excel in demanding applications like aerospace, electronics, and medical sectors, where reliability is essential. Hot melt acrylic adhesives have fast curing times, offer robust bonding capabilities, and are effective on a range of surfaces, which makes them perfect for industries with high manufacturing demands like assembly, woodworking, and automotive. Every technology segment meets particular application requirements, stimulating innovation and expansion in the worldwide acrylic adhesives market.

By Region:

The North American Acrylic Adhesives Market expected to drive growth during the forecast period. The area’s long-standing manufacturing sectors, such as automotive, construction, electronics, and communications, are significant users of acrylic adhesives, driving the need for advanced adhesive products. With the ongoing industrialization and economic growth in North America, the demand for sophisticated adhesive systems remains high. Moreover, strict environmental regulations that promote environmentally friendly products like low-VOC acrylic adhesives contribute to the growth of the market. Acrylic adhesives adhere to strict environmental standards, making them more widely adopted in different industries. Advancements in technology for making adhesives have also enhanced their ability to bond strongly and be flexible, making them appropriate for various surfaces. The demand for acrylic adhesives is predicted to stay strong in North American industries, strengthening the region’s leading position in the global market as it continues to develop.

If you require any specific information that is not covered currently, we will provide the same as a part of the customization >> https://introspectivemarketresearch.com/custom-research/17084

Comprehensive Offerings:

- Historical Market Size and Competitive Analysis (2017–2023): Detailed assessment of market size and competitive landscape over the past years.

- Historical Pricing Trends and Regional Price Curve (2017–2023): Analysis of historical pricing data and price trends across different regions.

- Market Size, Share, and Forecast by Segment (2024–2032): Projections and detailed insights into market size, share, and future growth by segment.

- Market Dynamics: In-depth analysis of growth drivers, restraints, opportunities, and key trends, with a focus on regional variations.

- Market Trend Analysis: Evaluation of emerging trends that are shaping the market landscape.

- Import and Export Analysis: Examination of trade patterns and their impact on market dynamics.

- Market Segmentation: Comprehensive analysis of market segments and sub-segments, with a regional breakdown.

- Competitive Landscape: Strategic profiles of key players across regions, including competitive benchmarking.

- PESTLE Analysis: Evaluation of the market through Political, Economic, Social, Technological, Legal, and Environmental factors.

- PORTER’s Five Forces Analysis: Assessment of competitive forces influencing the market.

- Industry Value Chain Analysis: Examination of the value chain to identify key stages and contributors.

- Legal and Regulatory Environment by Region: Analysis of the legal landscape and its implications for business operations.

- Strategic Opportunities and SWOT Analysis: Identification of lucrative business opportunities, coupled with a SWOT analysis.

- Conclusion and Strategic Recommendations: Final insights and actionable recommendations for stakeholders.

Related Report Links:

Biobased Adhesives Market: Biobased Adhesives Market Size Was Valued at USD 7.99 Billion in 2023, and is Projected to Reach USD 18.83 Billion by 2032, Growing at a CAGR of 10.00% From 2024-2032.

Structural Adhesives Market: Structural Adhesives Market Size Was Valued at USD 21.4 Billion in 2023, and is Projected to Reach USD 36.5 Billion by 2032, Growing at a CAGR of 6.1% From 2024-2032.

Automotive Adhesives Market: Global Automotive Adhesives Market was valued at USD 4.63 billion in 2023 and is expected to reach USD 6.74 billion by the year 2032, at a CAGR of 4.26%.

Acrylic Sheet Surface Protection Films Market: The global Acrylic Sheet Surface Protection Films Market Size Was Valued at USD 161.24 Million in 2023 and is Projected to Reach USD 239.62 Million by 2032, Growing at a CAGR of 4.50% From 2024-2032.

Adhesives And Sealants Market: Adhesives And Sealants Market Size Was Valued at USD 71.4 Billion in 2023, and is Projected to Reach USD 121.7 Billion by 2032, Growing at a CAGR of 6.1% From 2024-2032.

Electric Vehicle Adhesives Market: The size of the electric vehicle adhesive market was valued at USD 314.20 Million in 2023 and is Projected to Reach USD 2,241.74 Million by 2032, Growing at a CAGR of 24.4% From 2024 to 2032.

Wood Adhesives Market: Wood Adhesives Market Size Was Valued at USD 7.45 Billion in 2023, and is Projected to Reach USD 15.78 Billion by 2032, Growing at a CAGR of 8.7% From 2024-2032.

Electrically Conductive Adhesives Market: Global Electrically Conductive Adhesives Market Size Was Valued at USD 2.64 Billion In 2023 And Is Projected to Reach USD 10.20 Billion By 2032, Growing at A CAGR of 16.21% From 2024 To 2032.

Bonded abrasives Market: Bonded abrasives Market Size is Valued at USD 12.16 Billion in 2023 and is Projected to Reach USD 18.10 Billion by 2032, Growing at a CAGR of 5.10% From 2024-2032.

Acrylic Rubber Market: Global Acrylic Rubber Market Size Was Valued at USD 1134.19 Million in 2022 and is Projected to Reach USD 2054.63 Million by 2030, Growing at a CAGR of 7.71 % From 2023-2030.

About Us:

Introspective Market Research is a premier global market research firm, leveraging big data and advanced analytics to provide strategic insights and consulting solutions that empower clients to anticipate future market dynamics. Our team of experts at IMR enables businesses to gain a comprehensive understanding of historical and current market trends, offering a clear vision for future developments.

Our strong professional network with industry-leading companies grants us access to critical market data, ensuring the generation of precise research data tables and the highest level of accuracy in market forecasting. Under the leadership of CEO Mrs. Swati Kalagate, who fosters a culture of excellence, we are committed to delivering high-quality data and supporting our clients in achieving their business goals.

The insights in our reports are derived from primary interviews with key executives of top companies in the relevant sectors. Our robust secondary data collection process includes extensive online and offline research, coupled with in-depth discussions with knowledgeable industry professionals and analysts.

Contact Us:

Canada Office

Introspective Market Research Private Limited, 138 Downes Street Unit 6203- M5E 0E4, Toronto, Canada.

APAC Office

Introspective Market Research Private Limited, Office No. 401, Saudamini Commercial Complex, Kothrud, Pune, India 411038

Ph no: +91-81800-96367 / +91-7410103736

Email: sales@introspectivemarketresearch.com

LinkedIn| Twitter| Facebook | Instagram

Ours Websites : https://introspectivemarketresearch.com | https://imrknowledgecluster.com/knowledge-cluster | https://imrtechsolutions.com | https://imrnewswire.com/ | https://marketnresearch.de |

![]()