US & Canada, March 27, 2025 (GLOBE NEWSWIRE) — According to a new comprehensive report from The Insight Partners, “the global CNC machine Market Size and Forecast (2025 – 2031), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Machine Type (Lathe Machines, Milling Machines, Laser Machines, Grinding Machines, Welding Machines, Others); End-user Industry (Aerospace and Defense, Automotive, Industrial, Metals and MIning, Power and Energy, Others), and Geography”.

For More Information and To Stay Updated on The Latest Developments in The CNC machine Market, Download The Sample Pages: https://www.theinsightpartners.com/sample/TIPRE00006648/

The report runs an in-depth analysis of market trends, key players, and future opportunities. Different types CNC machine include lathe machines, milling machines, laser machines, grinding machines, welding machines, others. CNC machines manufacturers procure specific grades of materials from raw material suppliers and process them further to develop the final product.

For Detailed CNC machine Market Insights, Visit: https://www.theinsightpartners.com/reports/cnc-machine-market

Market Overview and Growth Trajectory:

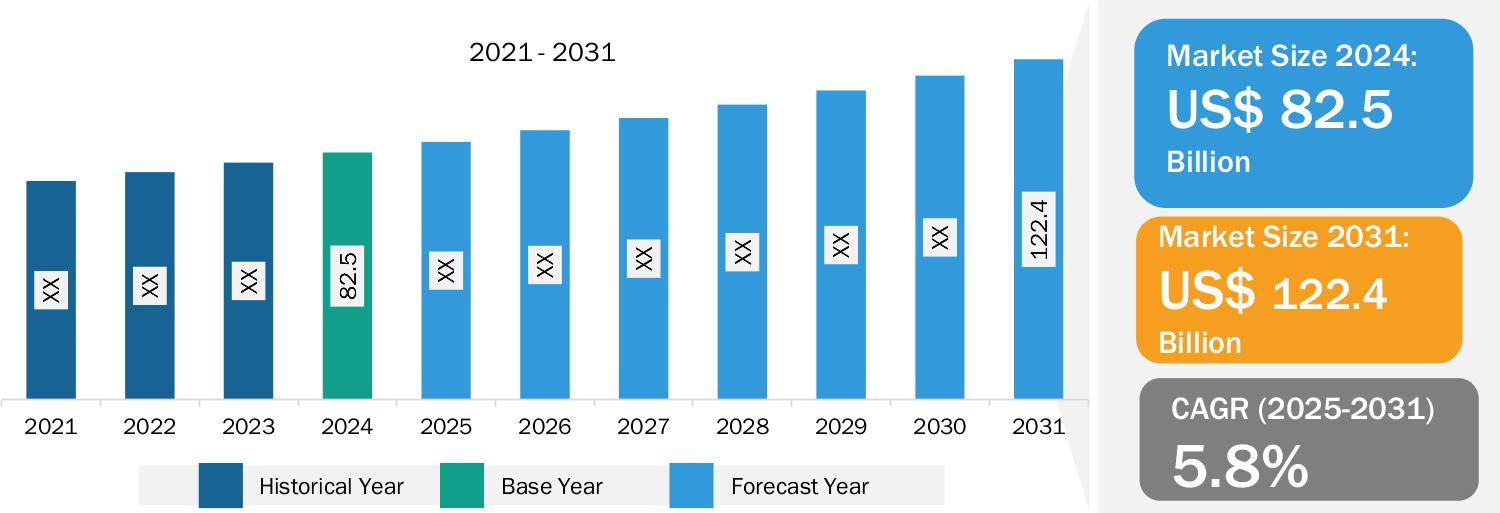

CNC machine Market Growth: The CNC machine market is expected to reach US$ 122.4 billion by 2031 from US$ 82.5 billion in 2024; it is expected to record a CAGR of 5.8% during the forecast period. Rapid industrialization in the manufacturing sector and rising foreign direct investment in developing countries is one of the factors that is driving the market growth. CNC machines are used to automate the process of manufacturing parts, allowing for greater consistency and precision. CNC machines are used to create highly precise components and parts with tight tolerances. This is critical in industries such as aerospace, automotive, and medical device manufacturing and many other industries. Growing industrial sector investments across the globe drive the CNC machine market growth. Globally, there was an increase in industrial sector investment by 2.3% in 2023 as compared to 2022, according to the United Nations Industrial Development Organization (UNIDO).Increasing investment in the development of industrial sectors across developing nations such as Mexico, South Korea, India, Brazil, and others drives market growth.

According to the World Bank Report in 2022, the industrial and services sector in Mexico accounted for 32.1% of the country’s GDP. The industrial sector in Mexico, including mining, manufacturing, oil, & gas, has contributed between 25% and 35% of the overall GDP. The Mexico CNC machine market is driven by increasing industrial activities and rising foreign trade. In 2023, Mexico’s Ministry of Economy reported an increase in foreign direct investments (FDIs) by 27%, reaching US$ 36 billion; 50% of this investment is in the manufacturing sector in Mexico. From January 2024 to June 2024, FDIs in Mexico reached US$ 31.1 billion across several industrial sectors. Mexico’s overall manufacturing output for 2023 was valued at US$ 360.73 billion, which increased by 14.73% compared to 2022. Such increasing investment in the manufacturing sector has created a massive demand for CNC machines.

Rising Investment in the Aerospace and Defense Sector Drives the CNC Machines Market Growth: Global aerospace and defense spending continues to rise as nations prioritize modernizing their forces to address new threats. The US Department of Defense raised its budget for fiscal year 2024 to US$ 842 billion, i.e., US$ 100 billion more than the budget allocated in FY 2022; these allocations emphasize integrating technologies such as AI, automation, and advanced manufacturing into defense systems. Moreover, the aerospace and defense sector generated US$ 425 billion in economic value in 2023, representing 1.6% of the nominal GDP of the US. Thus, significant investments in the aerospace and defense sector bolster the growth of CNC machines in the market. CNC machines play a critical role in the aerospace and defense sectors, where precision, reliability, and quality are paramount. These industries require highly specialized and complex components that must meet stringent safety, performance, and regulatory standards. CNC machines are utilized in various aspects of manufacturing within these sectors, ranging from prototypes to mass production of vital parts. CNC machines are widely used to produce critical engine components such as turbine blades, compressor blades, engine casings, and nozzle components.

Stay Updated on The Latest CNC machine Market Trends: https://www.theinsightpartners.com/sample/TIPRE00006648/

Increasing Adoption of CNC Machines in the Energy and Power Sector: CNC machines are widely used to manufacture various industrial components in the energy and power sector. In the energy and power sector, CNC machines are widely used to produce various components, such as seals, gears, pumps, and valves. These components are used in various energy and power-related applications, such as hydroelectric dams, wind turbines, and oil and gas drilling rigs. Increasing investment in the energy and power sector across the globe is creating significant opportunities for the CNC machines market growth. In 2022, the National Power System in Mexico’s power generation was 340,713 GWh, ~31.2% of the clean energy sources. In August 2024, the Federal Electricity Commission in Mexico and the government invested ~US$ 19.31 billion in energy generation-related projects. This investment funded the development of nearly 35 generation projects and 41 distribution projects. In 2023, five energy-related transmission projects were completed, with a total investment of $ 16.04 million. The rising investment in energy and power-related projects across the country is expected to create significant opportunities for the CNC machine market growth during the forecast period.

Geographical Insights: In 2024, Asia Pacific led the market with a substantial revenue share, followed by North America and Europe. Asia Pacific is expected to register the highest CAGR during the forecast period.

CNC machine Market Segmentation, Applications, Geographical Insights:

- Based on type, the CNC machine market is divided into lathe machines, milling machines, laser machines, grinding machines, welding machines, others. The lathe machines segment is expected to account for the largest share in 2024.

- Based on propulsion type, the CNC machine market is categorized into hybrid, fully electric, electric hydrogen. The fully electric segment expected to dominated the market in 2025.

- Based on end-user industry, the CNC machine market is categorized into is segmented into aerospace and defense, automotive, industrial, metals and mining, power and energy, others. In 2024, industrial segment is expected to account for the largest share.

Need A Diverse Region or Sector? Customize Research to Suit Your Requirement: https://www.theinsightpartners.com/inquiry/TIPRE00006648/

Key Players and Competitive Landscape:

The CNC machine Market is characterized by the presence of several major players, including:

- DMG MORI

- Okuma Corporation

- Makino Inc.

- HaaS Automation

- JTEKT Corporation

- FANUC CORPORATION

- Yamazaki Mazak

- Trumpf

- AMADA

- Tormach

These companies are adopting strategies such as new product launches, joint ventures, and geographical expansion to maintain their competitive edge in the market.

CNC machine Market Recent Developments and Innovations:

- ” Mainland CNC Launched Advanced Precision Machines to revolutionize global manufacturing.”

- “Nidec completed us antitrust review for Makino Milling Machine acquisition.”

Purchase Premium Copy of Global CNC machine Market Size and Growth Report (2025-2031) at: https://www.theinsightpartners.com/buy/TIPRE00006648/

Conclusion:

The manufacturing sector across the globe is developing, with a major focus on advanced technologies such as industrial automation, robotics, the Internet of Things, artificial intelligence (AI), 3D printing, additive manufacturing, automation, wireless technologies, and autonomous vehicles. Industry 4.0 enables CNC machines to become part of a smart factory ecosystem. These machines can be connected to a central system, allowing operators to monitor machine health, production rates, and quality data in real time. IoT-enabled CNC machines can collect and transmit data such as temperature, vibration, and load, which can be analyzed to predict failures and optimize production processes. Such, rising industry 4.0 evolution along with growing adoption of advanced technologies is driving the major trend in the global CNC machines market growth.

The report from The Insight Partners, therefore, provides several stakeholders—including raw material providers, manufacturers, suppliers and distributors, and end users—with valuable insights into how to successfully navigate this evolving market landscape and unlock new opportunities.

Related Report Titles:

About Us:

The Insight Partners is a one stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Device, Technology, Media and Telecommunications, Chemicals and Materials.

Contact Us:

If you have any queries about this report or if you would like further information, please contact us:

Contact Person: Ankit Mathur

E-mail: ankit.mathur@theinsightpartners.com

Phone: +1-646-491-9876

website: https://www.theinsightpartners.com/

![]()