TOKYO, Nov 20, 2024 – (JCN Newswire) – Mitsubishi Heavy Industries, Ltd. (MHI), NTT Communications Corporation (NTT Com), and NEC Networks & System Integration Corporation (NESIC), will begin demonstration testing in December to increase the cooling capacity of data centers without major modifications to existing facilities by introducing high-performance servers equipped with two-phase direct-to-chip cooling(1) systems to data centers currently in operation. The demonstration test is being conducted in response to the adoption of a proposal to introduce systems using MHI’s two-phase direct-to-chip cooling to the data center, for a project from the Tokyo Metropolitan Government’s Bureau of Industrial and Labor Affairs to support the early practical application of technologies to advance the establishment of GX-related industries. This demonstration aims to achieve energy savings in server power consumption and reducing CO2 emissions by utilizing existing data center facilities.

1. Background

With the spread of generative AI and other technologies, the use of high-performance processors such as GPUs is increasing, necessitating the reinforcement of equipment due to the large power consumption and high heat output. To accommodate high-performance servers equipped with these processors, newly built data centers can adopt the latest cooling solutions. On the other hand, replacing existing equipment is challenging, and increased capital investment was an issue. Accordingly, there is a need for solutions that can reduce capital investment by effectively utilizing the facilities in existing data centers, reduce power consumption, and meet the cooling requirements of high heat generating servers.

2. Outline of the Demonstration Test

This demonstration will implement the cooling of high-performance servers using two-phase direct chip cooling provided by MHI in an operational air-cooled data center located in Tokyo, operated by NTT Com. In two-phase direct-to-chip cooling, an insulating refrigerant other than water is circulated in a two-phase (liquid/gas) manner to a cold plate on the processor inside the server for cooling. Since water is not used, there is no concern of malfunction even if the refrigerant leaks inside the server. In addition, the heat from the processor is efficiently dissipated, and the autonomous control of refrigerant circulation enhances power efficiency by using the two-phase cooling. NESIC will work with MHI to build the IT equipment and demonstrate the server operation. The test will demonstrate that the application of two-phase direct-to-chip cooling systems in conventional air-cooled data centers will enable the introduction of high-performance servers in currently operating data centers without major modifications to existing facilities.

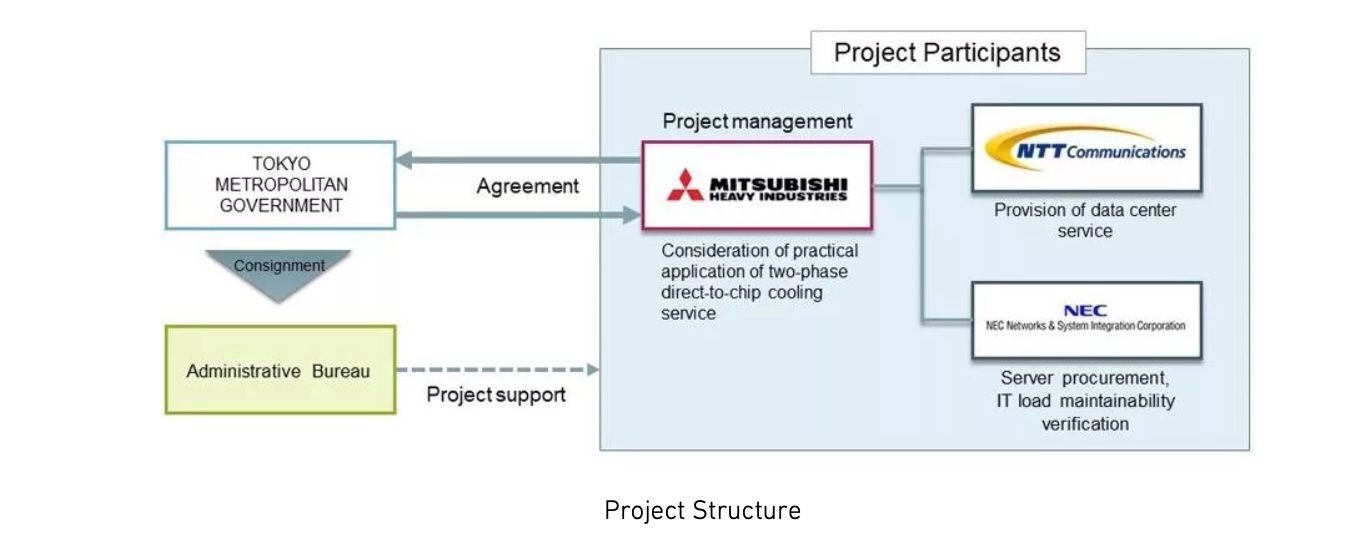

3. Roles of each company

MHI: Project management, supply of two-phase direct-to-chip cooling system, and demonstration testing

NTT Com: Supply of data center services

NESIC: Server procurement, IT load and operation testing

4. Future Prospects

MHI Group will provide a one-stop data center utility solution for highly reliable and high efficiency power supply units, cooling systems, monitoring systems, and integrated control systems to meet the expected growth in AI data centers market. By using Green ICT, MHI Group aims to contribute to the realization of a carbon neutral world and the conservation of the global environment.

NTT Com, to realize a sustainable world, is advancing the adoption of solutions that utilize two-phase direct-to-chip cooling, as well as IOWN APN(2), and Green Nexcenter®, a colocation service that supports liquid-cooled server devices. By leveraging green ICT, NTT Com will meet customer needs for generative AI and high-performance GPUs, as well as the new communication network IOWN APN.

NESIC will leverage its strength in comprehensive system integration capabilities to develop and support solutions for next-generation data centers that contribute to carbon neutrality, and contribute to the conservation of the global environment.

(1) Two-phase direct-to-chip cooling is a technology in which an insulating refrigerant is circulated in a two-phase manner to a cold plate on a semiconductor chip (processor) inside a server, for cooling without using water.

(2) IOWN is a network and information processing platform that utilizes optical-related technologies and information processing technologies for the realization of a smart society. “IOWN®” is a trademark or registered trademark of Japan Telegraph and Telephone Corporation. APN is an all-optical network that utilizes photonics-based technologies across the entire system, from the network to the terminal.

Related Links

Direct-to-chip cooling solutions introduction website

www.mhi.com/products/infrastructure/direct_chip.html

Companies selected to receive support of practical application of new GX-related technologies

www.metro.tokyo.lg.jp/tosei/hodohappyo/press/2024/10/01/18.html (Japanese)

[Press Release] “NTT Com Launches “Green Nexcenter™” Ultra Energy-Saving Data Center Service Compatible with Liquid-Cooled Server Equipment”

https://www.ntt.com/about-us/press-releases/news/article/2023/1004_2.html

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.