UV LED curing has evolved a long way since the initial discovery of aluminum gallium nitride LED at the turn of the century. This technology that generates energy in the 365-405 nm ‘UVA’ wavelengths is no longer insignificant as many people switch out mercury vapor lamp systems for this eco-friendly low temperature process. In this guide, we’ll look at the benefits and technologies of LED curing systems for label printing.

What Is UV LED Curing?

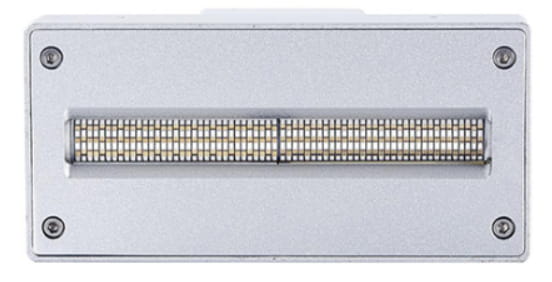

UV LED curing is a process that uses ultraviolet light-emitting diodes to quickly harden liquids. It has many applications but is mainly used in inkjet systems to polymerize images on objects ranging from paper, plastics, and 3-D parts.

Mercury vapor lamps have long been the main lamp system in UV inkjet printers, and while they have their own set of advantages, including broad spectrum UV light, they tend to consume a lot of energy and generate substantial heat and ozone.

Their usage has a long-term effect on the environment which means they are under strict regulatory scrutiny and must be disposed of carefully, usually at a cost.

In contrast, LEDs emit light in the 365-405 nm ‘UVA’ wavelengths, which is a monochromatic spectrum. While this means you can’t fully capitalize on the reactivity of the ink components in the system and maximize the speed and productivity of the ink, you’ll benefit from advantages such as low power consumption, and low heat emission. Here is a detailed breakdown of the benefits of UV LED curing:

It Uses Less Ink

UV LED curing cures ink in just a single pass, minimizing ink loss via diffusion and absorption into the printing material. This reduces the amount of ink needed for a print. In fact, studies show UV LED curing uses 20% less ink than conventional printing techniques and it generally results in vibrant and visually pleasing prints.

Clean and Cooler Curing Technique

LED UV curing doesn’t generate infrared heat, meaning it operates at remarkably lower temperatures than mercury vapor lamp curing systems and cures faster, preventing ink from seeping through the material and causing a mess.

Additionally, any heat generated by the process disperses quickly leaving the substrate cooler. Indeed, UV LED curing makes it possible to print on heat-sensitive materials such as plastics and films that wouldn’t be possible with mercury vapor lamps.

Elegant Printing Effects Are Possible

UV LED curing also makes it possible to print two or more colors in quick order without the need for intermittent drying time. This wet-on-wet printing technique is useful for creating high-end effects on prints, including obvious tactile variation between different areas of the material.

Faster Production Cycle

Apart from the obvious advantages of no drying step, faster curing, less heat generation and substrate distortion, UV LED curing is a simple setup, ensuring fast turnaround times without reduction in quality.

In summary, LED lamps in inkjet systems are energy-efficient, longer-lasting curing solutions that produce high quality prints faster without producing ozone. They can be used in a wide range of printing applications including label printing.

That’s why IUV is invested a lot of R&D effort to create reliable LED technology and accelerate its adoption in inkjet printing. Whatever the application or location, our experts are dedicated to meeting your curing needs. Visit our products page to learn more.