X-Ray inspection systems are a reliable form of quality control that helps businesses streamline the production and assessment process for safety, accuracy, and compliance verification. With ever-increasing demands for industrial production rates at cost-effective prices, X-ray inspection systems provide companies with an efficient system to detect defects before they leave the factory.

By employing advanced technologies such as 3D imaging software, radiation hardness testing, and digital signal processing (DSP), companies can quickly move their products from concept to market without sacrificing quality or performance standards.

Having this in mind, this article will discuss in detail what an X-ray inspection system is, how it works, and its numerous benefits.

Introducing X-Ray Inspection Systems – What They Are And How They Work

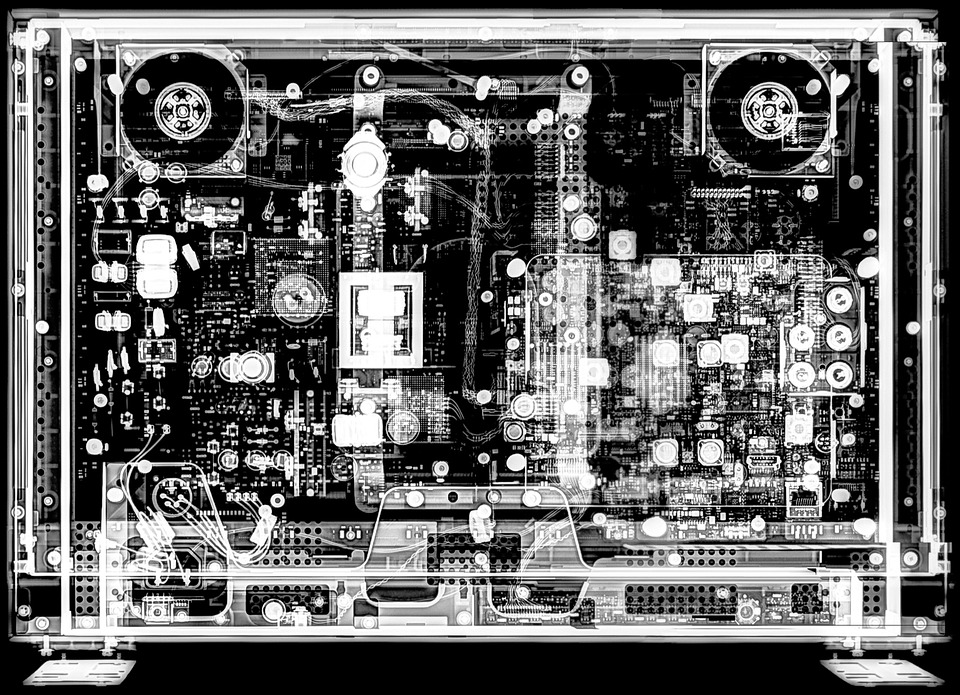

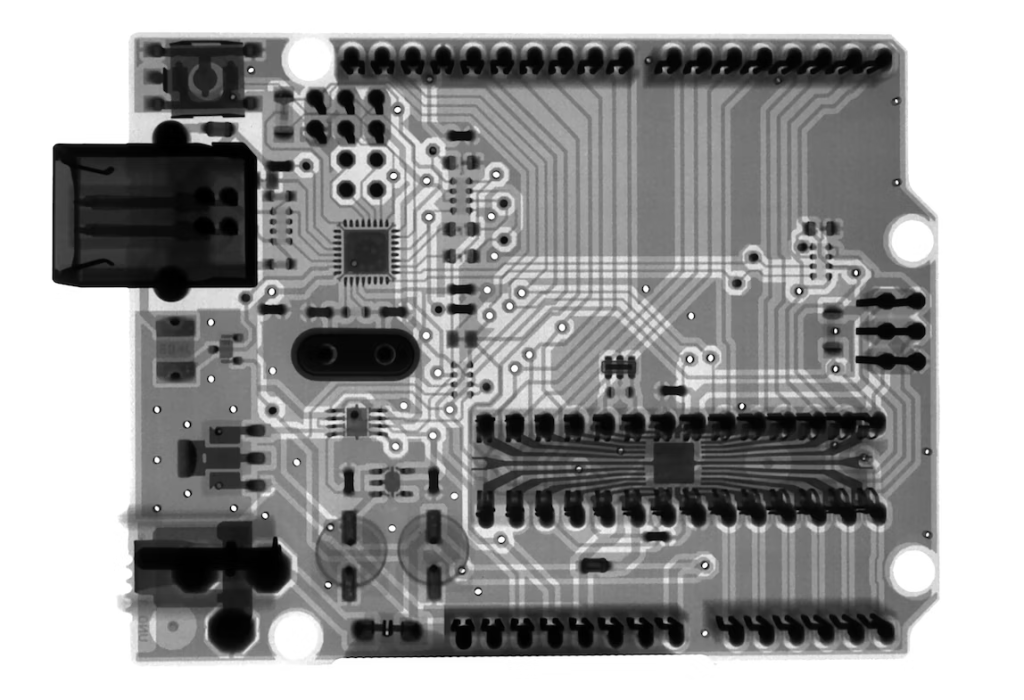

X-ray inspection systems work on the principle of penetrating radiation to identify the internal structure of products for a quick and thorough inspection. The technology operates by detecting differences in density and atomic number, highlighting any defects or contaminants in the product. With the ability to detect contaminants as small as 0.2mm, X-ray inspection systems are a reliable and indispensable tool for companies looking to deliver premium-quality products to customers.

From food and beverage to pharmaceuticals and beyond, X-ray inspection systems have proven to be an essential investment for businesses looking to stay ahead in the market.

Choosing the right X-ray inspection system for your business is a crucial decision that can have a major impact on your operations, product quality, and ultimately, your bottom line. With so many different options and configurations available, it can be overwhelming to determine which high-quality X-ray inspection equipment is the best fit for your specific needs. That’s why it’s essential to work with a professional X-ray inspection provider who can guide you through the selection process based on your product type, packaging, throughput requirements, and other key factors.

By selecting the right system, you can achieve higher levels of accuracy, efficiency, and consistency in your inspection process, leading to increased customer satisfaction and overall success for your business.

The Benefits Of Using X-Ray Inspection Systems In Quality Control

X-ray inspection systems have revolutionized the way we ensure quality control. These systems provide non-destructive testing technology, allowing for the inspection of packaged products without the need for opening or destroying them. They can detect contaminants such as metal, glass, and other foreign objects, as well as defects in the product itself, such as missing components or cracks.

This enables manufacturers to identify and isolate problematic products before they reach the consumer, reducing the risk of recalls or safety issues. Not only does this benefit the end user, but it also saves the manufacturer time and money by preventing costly product recalls and reducing waste.

For instance, in the food industry, X-ray inspection systems are used to detect contaminants such as insects and other foreign objects that may be difficult to identify with the naked eye. X-ray technology is often utilized for package integrity testing, ensuring that products are properly sealed and safe before entering the market.

Types Of X-Ray Inspection Systems

X-ray inspection technology has come a long way, and today’s systems are highly advanced and sophisticated. Whether it’s for detecting contaminants in food products, inspecting cargo for drugs and explosives, or inspecting components in an industrial setting, there are several types of X-ray inspection systems available to meet diverse needs.

Some of the common types include cabinet X-ray systems, conveyorized X-ray systems, and handheld X-ray systems. Each has its unique advantages and limitations, and the choice of the system depends on factors such as the size and shape of the objects being inspected, the level of sensitivity required, and the throughput rate.

With the ability to detect even the smallest contaminants that can be harmful to consumers, X-ray inspection systems are crucial tools for ensuring product safety and quality.

Optimizing Your X-Ray Inspection System For Maximum Efficiency

When it comes to X-ray inspection systems, efficiency is key. Ensuring that your system is optimized for maximum efficiency can not only save time but also improve the accuracy of your inspections. There are a variety of methods for optimizing your X-ray inspection system, including adjusting the voltage and current settings, using proper calibration tools, and ensuring proper maintenance of the system.

By focusing on these factors and constantly analyzing and refining your approach, you can achieve the highest level of efficiency with your X-ray inspection system. This can help you to identify any potential issues or defects with products quickly and accurately, improving the overall quality control process for your organization.

Tips To Maintain A High Level Of Quality With An X-Ray Inspection System

When it comes to X-ray inspection, maintaining a high level of quality is essential to ensure accurate and reliable results. To achieve this, there are several tips that you can follow.

Firstly, it’s important to regularly calibrate your X-ray inspection system to ensure that it’s detecting defects as accurately as possible. Secondly, keep your system clean and well-maintained to prevent any potential issues from arising. It’s also recommended to perform regular inspections and audits of your X-ray system to identify areas for improvement and ensure that it’s performing optimally. Finally, invest in high-quality training for your operators to ensure that they can effectively and efficiently use the system.

By following these tips, you can help to maintain a high level of quality with your X-ray inspection system and ensure that you’re achieving accurate and reliable results.

Yes, X-Ray inspection systems are one of the best ways to ensure the highest quality standards in any industry. They provide an efficient and cost-effective solution to improving process accuracy, ensuring that every product passes with flying colors. With varying types of X-Ray systems available, as well as optimization techniques to make your system as efficient as possible, your business can benefit immensely from using them. Regular maintenance and inspections will also help keep the system running at maximum efficiency and tests help ensure that products meet the highest standards possible.

With these tips in mind, you’re well on your way to having an effective X-Ray inspection system for your company’s quality control needs.